overhead shot-peening

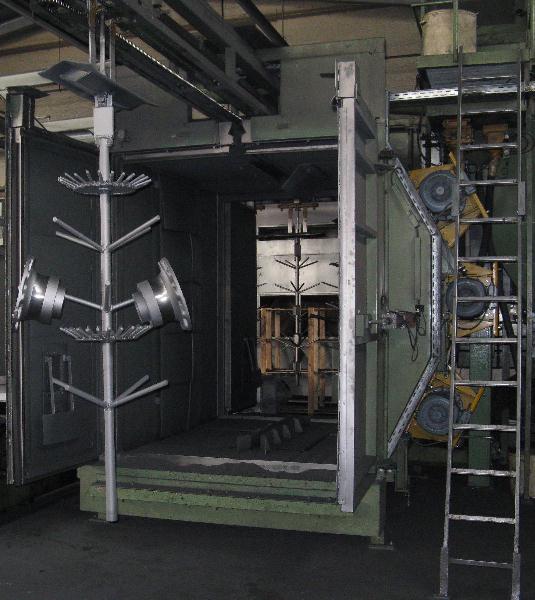

At the Gottmadingen location, we work with a shot-peening installation, mostly for series parts:

- First shot-peening after casting: directly after taking the castings out of the foundry sand

- Cleaning of metal-parts: to eliminate corrosion, flitter and old paint

- Final shot-peening of castings: to achieve dirt-free and dust-free surfaces, especially just before painting or before assembly in engines and transmissions

- Use of 3 turbo blasters for high power and reduction of time and costs

The main advantages of a "overhead feeding system" are:

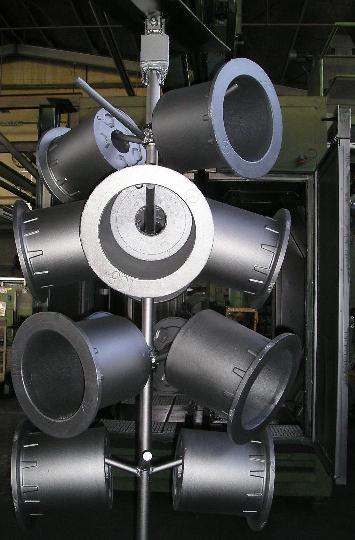

- The parts do not touch each other and do not fall about; therefore there is no bending of thin-walled structures and no surface damage

- The parts are perfectly accessible to the abrasive; even difficult areas in deep recesses can be reached in automated processes, see the picture below

- Also heavy parts up to 1000 kg can be hooked onto the support structure and then shot-peened at low cost in our automated process

This in-house shot-peening centre complements ideally the press-line, the NC-machines and the paint-shop.