guideways out of turcite, copper and spring steel

We manufacture guideways out of Turcite:

- Turcite is a modern plastic material with metal-inclusions, with a low friction-factor and slip-stick-free, and is still working in absence of lubrication (Trelleborg / ex Busak and Shamban)

- Turcite must be glued very carefully onto the machined surface.

- After drying the guideway, together with the complete machine bed, is milled and drilled and ground to final dimensions.

- The Turcite-surface is quite soft and suitable for guiding delicate parts in the 0,01 mm tolerance area, but at the same time it is also prone to surface-defects due to handling.

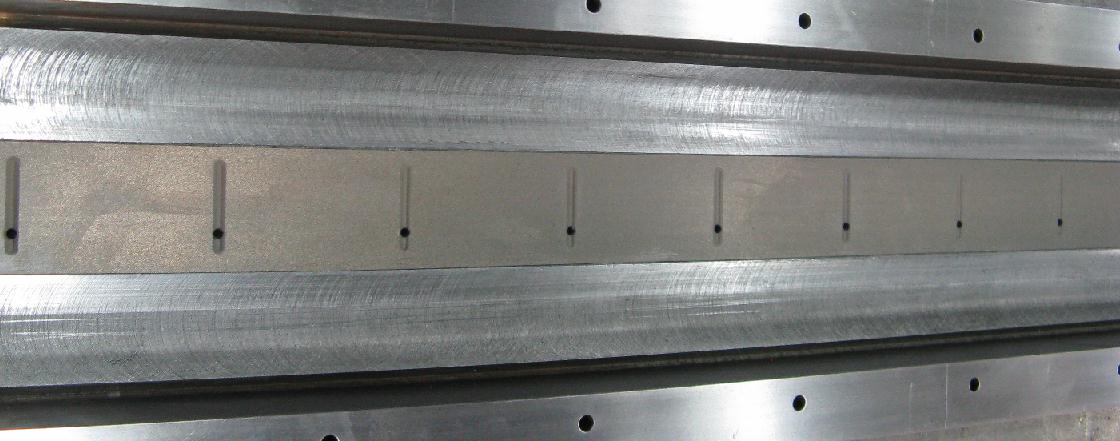

ground surface with oil-lubrication grooves

We manufacture guideways out of copper and bronce:

- Copper and bronze are classic materials, offering the optimum combination of hardness, friction in absence of lubrication, and cost.

- Copper rails can be screwed or glued onto the machine bed. Especially gluing results in a high resistance to shearing forces.

- After fixation the guideway, together with the complete machine bed, is milled and drilled and ground to final dimensions.

machined copper guideways

We manufacture guideways out of flame-sprayed metal:

- in restricted areas it is often not possible to mount separate guideways. In these cases we can flame-spray metal.

- The flame-sprayed metal, together with the complete machine bed, is milled and drilled and ground to final dimensions.

- In order to protect the know-how of our customers, we regret not being able to show any pictures.

- Spring steel has a high hardness of 1600 - 1800 N/mm2 and therefore is best suited for a long lifetime.

- The band of spring steel is either clamped down or glued onto the machine bed; due to the low height it is unusual to use screws.

- After fixation the spring steel, together with the complete machine bed, is milled and drilled and ground to final dimensions.

- Due to its high hardness any further machining is difficult and unusual. Therefore spring steel guideways are not receiving lubrication from below.

Other guideways:

- Alternatively to the above-mentioned 4 systems we can also use linear guide-rails that are bolted down onto the bed (INA, Bosch, THK, etc.)

- When using cast machine beds, the surface in the guideway-area can also be hardened by induction. But since large castings are expensive, this system is more often used for smaller machines that are built in large series.