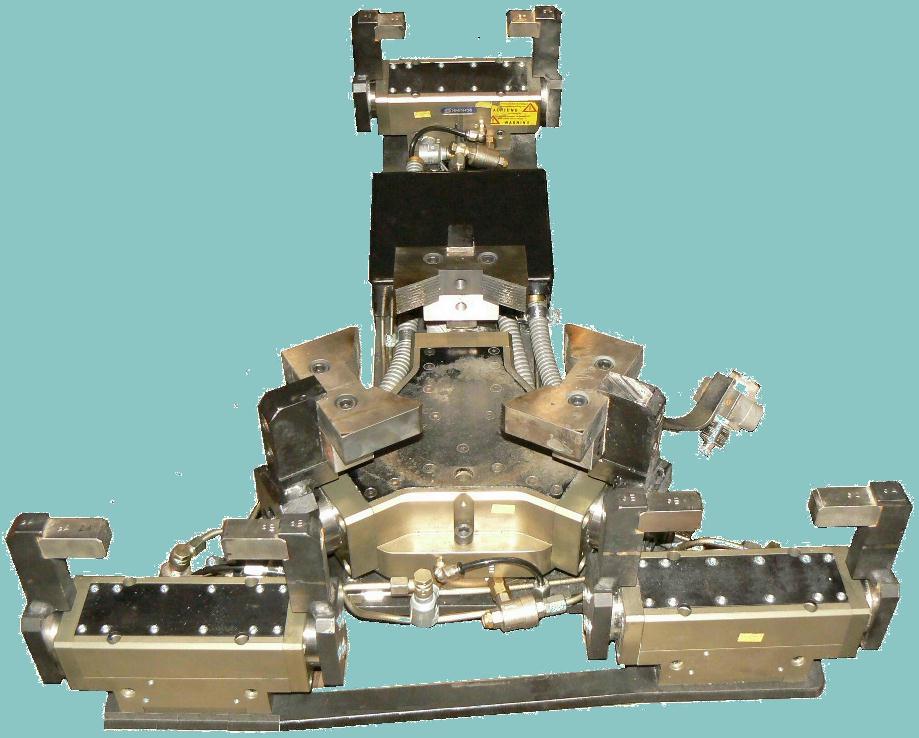

robotic grippers

We develop, design and manufacture complete robotic gripper-solutions:

- for handling of castings in foundries

- for transport of melt from oven to die (sand-casting, die-casting, gravity casting)

- for transport of parts in body-in-white welding lines

- cycle times, speeding-up ramps and other timing aspects

- admissible working zones as defines by dies, tooling and fixtures

- as well as by machines, ovens and safety fences

- any introduction of chips or of spraying cooling water

- special electrical connectors and thermal and water protection

- heat radiated from ovens and melt

- total weight of grippers, use of components out of high strength aluminium

- maximum robot load, leverage effects and permissible accelerations

- assembly and in-site measurement of 3D-surface-parts and -grippers

- safety aspects of workers, safety fences

- reliability, standard components, proven solutions

- tool-change couplings, even complete gripper parking lots

- complete programming of robot and gripper movements for KUKA, ABB and FANUC

- integration of new programs in central computers for large plants

- prevailing EU-norms and safety laws, CE-compatibility and CE-sign

- tricks and experience from recent projects

- tryout of new gripper systems on our own robot

Our top-notch customers for complete robot-gripper-solutions are:

- Georg Fischer

- Volkswagen

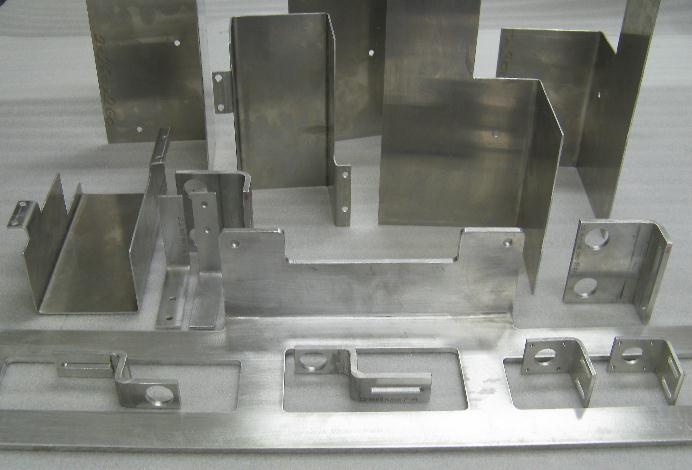

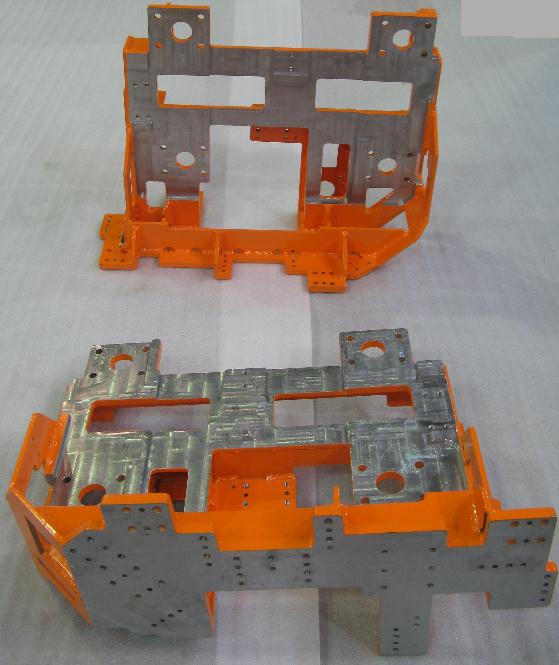

In order to reduce weights on moving robots, we use high-strength aluminium (aircraft-aluminium):

- from blanks or as special castings

- we are able to bend high-strength aluminium to small radii under heat

- we regularly use heli-coils for threads with highest "pull-out-resistance"

If

Why don't you profit from our experience?