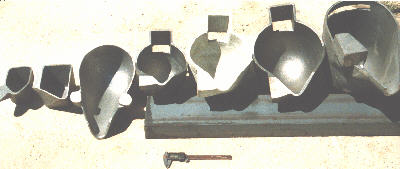

ladles for aluminium and other non-ferric metal castings

We deliver all kinds of ladles for non-ferric metal castings.

- For diecasting, gravity casting, sand casting and castings for polystyrene

- The ladles are made from high quality, thin-walled and long-life hard castings, not from sheet metal.

- We have more than 110 different patterns and more than 1000 ladles "on stock" (in East and West).

- The ladles can contain melt weights up to 100 kg

- We are able to deliver ladles for new projects quickly; either from stock or true handmade prototypes or from new patterns.

- We are the development partner of several manufacturers of robots and casting machines

- We deliver to all large aluminium foundries in the automotive industry, in Germany and Eastern Europe

- We give on-site advice to our customers in case of exuberant wear (tribology).

- to BMW, Daimler, Ford and Volkswagen

- to robot manufactures ABB, Fanuc, Kuka and Reis

- for handling equipment from Ciropress, Pomac, Schmitz & Apelt, Sprötze, Gauss

- for diecasting machines from Bühler, Coloseo, Frech, Idra, Müller-Weingarten, UBE

- to a large number of aluminium foundries in Western and Eastern Europe

Ceramic Ladles

We deliver two kinds of ceramic ladles:

Ladles with ceramic covering, colour black:

- The Ceramic is heat resistant up to 1100 °C. The Covering is not composed of enamel but an industrial ceramic.

- We can offer the whole spectrum of more than 100 models on stock.

- We can cover ladles and rins placed by our clients with ceramics.

- The ladles reach furthermore the whole strength between holding and melt

- The ladles should still be covered with a refractory layer to avoid the sticking of Aluminium on ceramic.

- The durability of ceramic covered ladles can be raised by this way. Though the experiences of different casting houses are difficult to compare.

Stainless Steel Ladles, colour dark grey:

- During two years of cooperation with a high-capacity casting house we have developed a Chrome Nickel melt, that reaches in real performance a higher durability than a full ceramic ladle! The advantages of casted ladles e.g. resistance against mill scale persist but a higher durability of six or more months can be added.

- Though these ladles are noticeable more expensive.

- We can offer the whole spectrum of more than 100 models on stock.

- The highest durability is reached by combining blackening and a ceramic covering

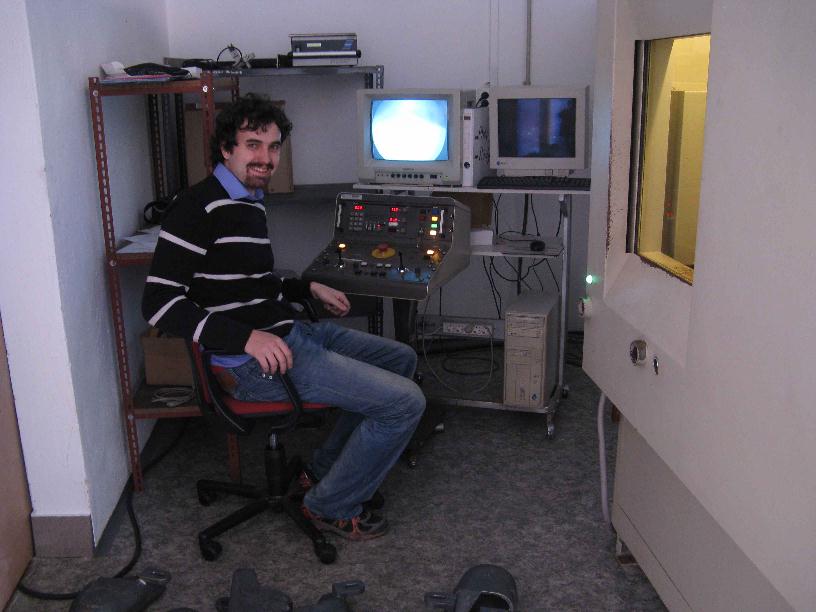

X-ray control of ladles

It is important that ladles are free of shrink holes. Only perfect castings can reach maximal durability.

Therefore we control 100 % of our ladles by X-ray!

X-ray analysis by a facility of Philips

The X-ray facility enables to control:

- iron castings

- aluminium or magnesium castings

The X-ray-facility was an expensive investment, but allows us to guaranty highest quality of the ladles.